(RE)CONNECTION

LumiPod is minimal, like the original cell.

A true cocoon of simplicity sits in the heart of nature, ready to welcome city dwellers in search of connection.

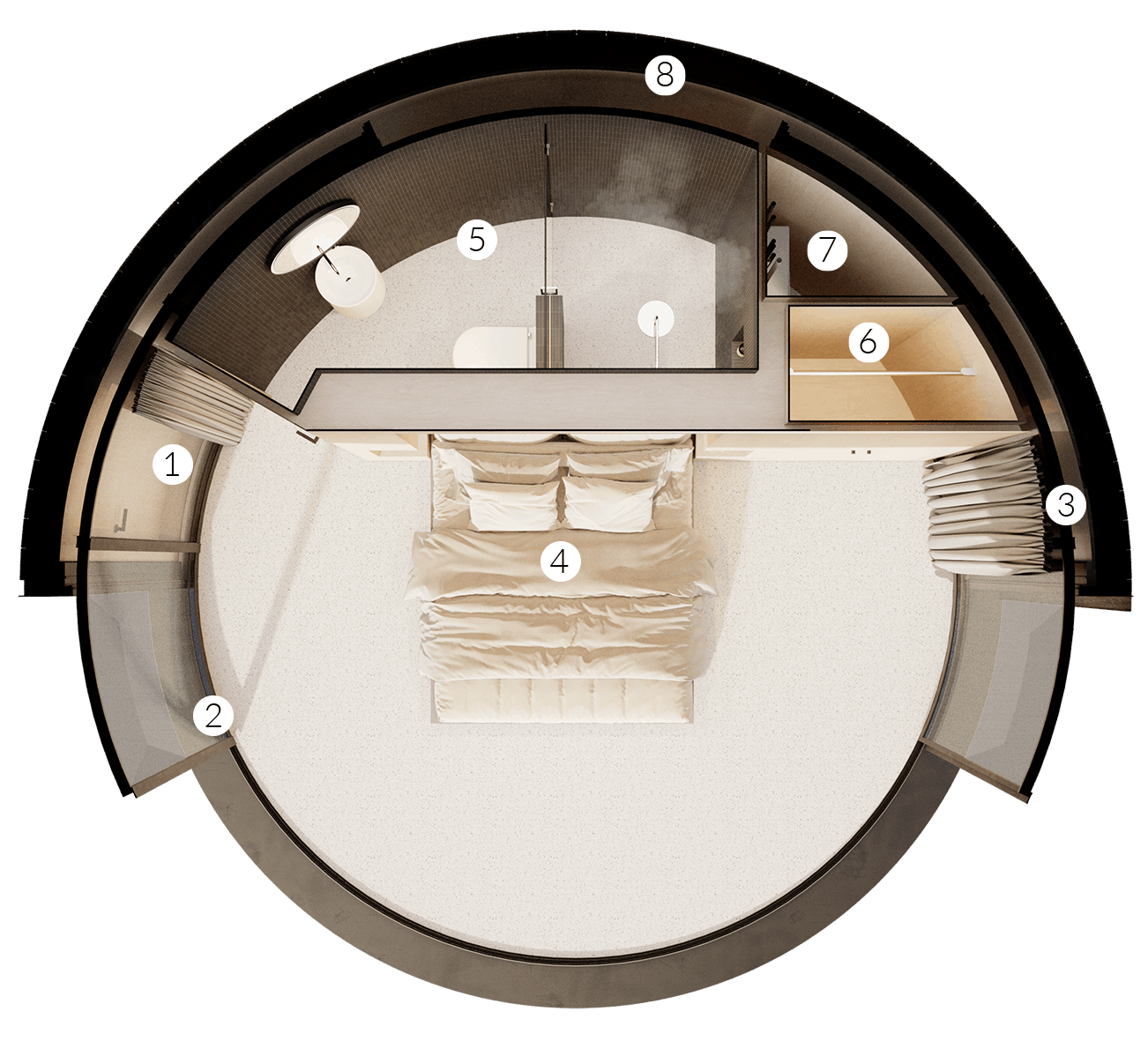

1. Curved entry door

2. Lumicene curved reversible window

3. Curtains

4. 14m² bedroom with panoramic view!

5. Bathroom and toilets

6. Wardrobe

7. Technical room

8. Curved wood-frame walls

1. Curved entry door

2. Lumicene curved reversible window.

3. Curtains

4. 14m² bedroom with panoramic view!

5. Bathroom and toilets

6. Wardrobe

7. Technical room

8. Curved wood-frame walls

INDOOR AND OUTDOOR LIVING

LumiPod is a high-end prefabricated cabin designed around a LUMICENE® window,

with patented curved and reversible joinery, allowing to rethink the relationship between indoors and outdoors, and providing the opportunity to reconnect with nature.

When closed, LumiPod is a comfortable cocoon fully immersed in nature.

With a simple gesture of the hand, LumiPod eliminates the inside-outside boundary making way for an unforgettable experience.

LUMIPOD FAMILY

LumiPod is available in various sizes, from 5.5 to 8 metres in diameter.

LumiPod 5, a minimalist hotel room of 18sqm, an office or a massage room.

LumiPod 6, a spacious room of 26sqm, a meeting room or a wellness room.

LumiPod 8, a family cocoon of 42sqm or luxury suite.

LumiPod Sauna, 2.5 metres in diameter, is now available to enrich

the LumiPod experience and offer an exceptional wellness space.

TECHNICAL DETAILS

Foundations

LumiPod requires ‘light’ foundation points. Depending on the soil type, different options can be considered. By default, screw piles are recommended as they minimise the impact on the installation site. Water and electricity connections will need to be prepared prior to installation.

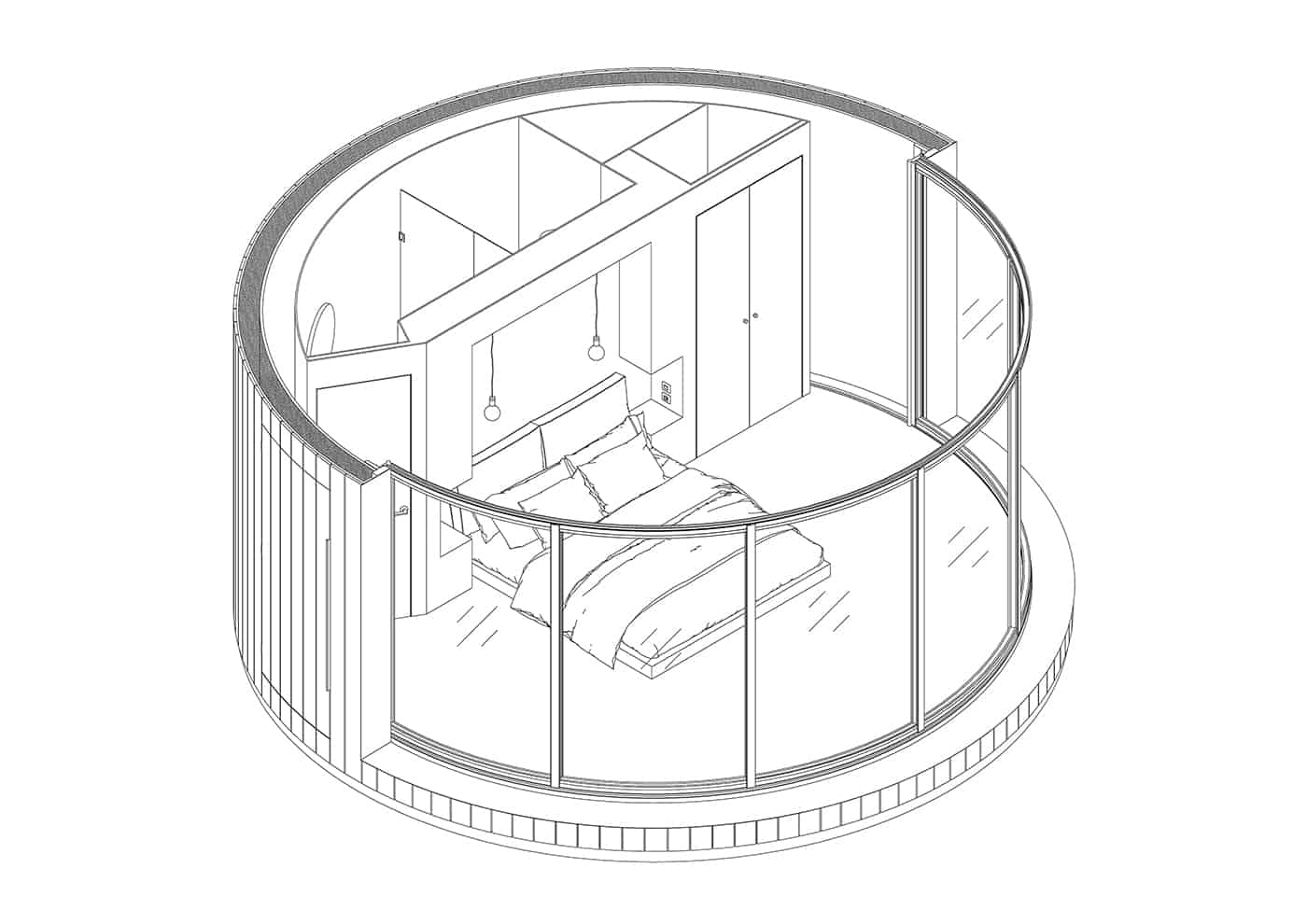

Structure

LumiPod’s structure is made of steel in order to guarantee the level of rigidity required for good functioning of the LUMICENE window. It consists of a frame laid on the foundation points; a rear module containing all the technical equipment, fully manufactured in the workshop; a front module bolted to the rear module directly onsite. The curved timber-framed exterior wall incorporates 20cm of glass wool, a rain screen on the exterior and a vapour barrier on the interior. The roof and floor are insulated with 8cm of polyurethane.

Roof

Waterproofing is achieved using a Firestone EPDM membrane installed in the workshop. Water pipes are incorporated into the rear poles.

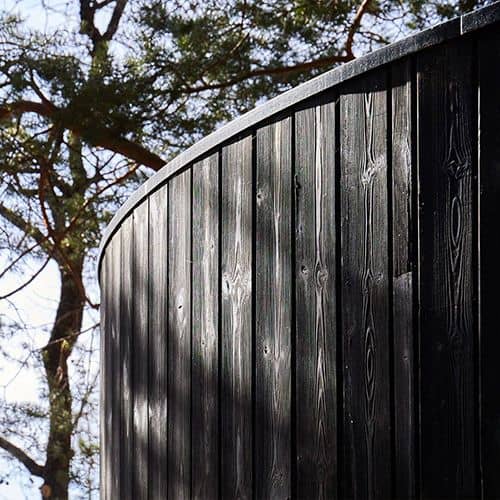

Exterior cladding

LumiPod is wrapped in an external cladding of thermo-stabilised Northern Pine that guarantees an increased stability of the wood with time. Several colours are available. Other cladding options can be considered so that LumiPod fits in perfectly with its environment.

Window

LumiPod is equipped with LUMICENE joinery made of curved glass with a circular slide. It consists of curved sashes sliding along a ring rail.

The aluminium profiles have a thermal break.

A curved rod holds blackout curtains that conceal the entire glass surface. These can be motorised as an option.

By default, the LUMICENE integrates a 6FE(20)6 (Ug 1.1 W / m2K) curved double glazing. Other options are available depending on weather conditions, including triple glazing 6FE(12)4(12)6.

LUMICENE is entirely manufactured by the Saint-Gobain Group in a factory based in Chambéry, France.

LumiPod is also equipped with a tilt and turn window frame in the bathroom.

Interior Design

LumiPod has been designed as a high-end hotel room. Great attention has been paid to the design and the choice of materials for the interior. The main unit is made of natural oak veneer with a matt finish. It includes a wardrobe positioned to the right of the bed, which can accommodate a suitcase, a minibar, a safe, and everything you need to spend a weekend in the middle of nature. The bed is like suspended, and integrated in a shallow niche. The floor is made of light oak parquet. Door handles and knobs come in an anodised sanded black finish. The lighting and temperature control equipment is made by JUNG.

Bathroom

The bathroom is equipped with a toilet, a basin, a shower, a heated towel rail and a wall niche.

The Axor fittings are in chrome steel, but other finishes are possible.

The floor features 60x60cm tiles and the walls 7.5×2.5cm mosaic tiles, both in anthracite grey. Other colours are available.

Heating and cooling

LumiPod is equipped with a Toshiba reversible air-conditioning system to manage both heating and cooling requirements.

A disbursement in the roof accommodates the outdoor unit.

LumiPod can be easily fitted with a wood burning stove unless the site requires cooling in summer.

The bathroom has an integrated ventilation system.

Water and electricity

In its current version, LumiPod must be connected to electricity, water and wastewater networks. A 100% off-grid version of LumiPod is under development.

Transport and installation

LumiPod has been designed to be compatible with both road and sea transport. The installation is coordinated by our teams, sometimes supported by local companies, depending on the installation site. A LumiPod can be assembled within 2 to 3 days (except foundations and networks which will have been prepared beforehand).

*Specifications for LumiPod 5. Drawings and specifications for the different LumiPod sizes are available on request.

*Specifications for LumiPod 5. Drawings and specifications for the different LumiPod sizes are available on request.

Foundations

LumiPod requires ‘light’ foundation points. Depending on the soil type, different options can be considered. By default, screw piles are recommended as they minimise the impact on the installation site. Water and electricity connections will need to be prepared prior to installation.

Structure

LumiPod’s structure is made of steel in order to guarantee the level of rigidity required for good functioning of the LUMICENE window. It consists of a frame laid on the foundation points; a rear module containing all the technical equipment and fully manufactured in the workshop; a front module bolted to the rear module directly onsite. The curved timber-framed exterior wall incorporates 20cm of glass wool, a rain screen on the exterior and a vapour barrier on the interior. The roof and floor are insulated with 8cm of polyurethane.

Roof

Waterproofing is achieved using a Firestone EPDM membrane installed in the workshop. Water pipes are incorporated into the rear poles.

Exterior cladding

LumiPod is wrapped in an external cladding of thermo-stabilised Northern Pine that guarantees an increased stability of the wood with time. Several colours are available. Other cladding options can be considered so that LumiPod fits in perfectly with its environment.

Window

LumiPod is equipped with LUMICENE joinery made of curved glass with a circular slide. It consists of sashes that slide along a ring rail.

The aluminum profiles have a thermal break.

A curved rod holds blackout curtains that conceal the entire glass surface. These can be motorised as an option.

By default the LUMICENE integrates a 6FE(20)6 (Ug 1.1 W / m2K) curved double glazing. Other options are available depending on weather conditions, including triple glazing 6FE(12)4(12)6.

LUMICENE is entirely manufactured by the Saint-Gobain Group in a factory based in Chambéry, France.

LumiPod is also equipped with a tilt and turn window frame in the bathroom.

Interior Design

LumiPod has been designed as a high-end hotel room. Great attention has been paid to the design and the choice of materials for the interior. The main unit is made of natural oak veneer with matt finish. It includes a wardrobe positioned to the right of the bed, which can accommodate a suitcase, a minibar, a safe, and everything you need to spend a weekend in the middle of nature.

The bed is like suspended, and integrated in a shallow niche. The floor is made of light oak parquet. Door handles and knobs come in an anodised sanded black finish.

The lighting and temperature control equipment is made by JUNG.

Bathroom

The bathroom is equipped with a toilet, a basin, a shower, a heated towel rail and a wall niche.

The Axor fittings are in chrome steel, but other finishes are possible.

The floors features 60x60cm tiles and the walls 7.5×2.5cm mosaic tiles, both in anthracite grey. Other colours are available.

Heating and cooling

LumiPod is equipped with a Toshiba reversible air-conditioning system to manage both heating and cooling requirements. A disbursement in the roof accommodates the outdoor unit.

LumiPod can be easily fitted with a wood burning stove unless the site requires cooling in summer.

The bathroom has an integrated ventilation system.

Water and electricity

In its current version, LumiPod must be connected to electricity, water and wastewater networks. A 100% off-grid version of LumiPod is under development.

Transport and installation

LumiPod has been designed to be compatible with both road and sea transport. The installation is coordinated by our teams, sometimes supported by local companies, depending on the installation site. A LumiPod can be assembled within 2 to 3 days (except foundations and networks which will have been prepared beforehand).

READY TO (RE)CONNECT ?

LumiPod is available in Europe with manufacturing lead times from 3 to 5 months.

LumiPod will soon be available in the US, Canada, Australia and New-Zealand.

Please contact us for any other destination. We will be happy to check the feasibility of your project.

ABOUT US

LUMICENE has created and patented a curved and reversible window in partnership with Saint-Gobain, and since 2019 has been developing LumiPod: high-end cabins entirely manufactured in our workshop in France.

©LUMIPOD by LUMICENE®

All rights reserved 2021 / Images : ©Oxygen / Scripts : Alexis Clément, Poids Plume

Photos : ©KévinDolmaire ©MauditSalaud ©GünterStandl ©JonathanLetoublon ©StevenRochat

422 rue de la Dombes 01700 Miribel Les Echets, FRANCE

+33 4 81 130 430

hello@lumi-pod.com